Custom Aluminum Heat Sink Solutions

⇀ Excellent Heat Dissipation & Mechanical Properties

⇀ Manufacturing Support from Design to Production

⇀ Customization Options for Various Applications

Aluminum Heat Sink Manufacturing Services by Teamsworld

Aluminum heat sinks are essential components in electronic devices, dissipating heat to prevent overheating and system failure. Their excellent thermal conductivity, lightweight nature, durability, and corrosion resistance make them ideal for various applications, such as consumer electronics, electrocommunication devices, lighting fixtures, industrial equipment, and more.

Teamsworld offers high-quality aluminum heat sinks tailored to your specific needs, with diverse sizes, shapes, fin densities, and alloy options. Leveraging Design For Manufacturing (DFM) support, our services cover the entire production process. Our advanced equipment also helps to ensure precise tolerances, high reliability, and optimal thermal performance for your custom heat sinks.

Types of Aluminum Heat Sinks Available

Die-Cast Custom Heat Sink

Die-cast aluminum heat sinks are cost-effective options for medium to high-volume production. They are formed by injecting molten aluminum alloy into a mold under high pressure. This allows precise control when creating complex designs that are difficult to achieve through other methods, such as thin fins which can help enhance surface area for better heat dissipation.

Forged Custom Heat Sink

Forged aluminum heat sinks have exceptional material density and durability. They are manufactured through forging techniques that involve shaping heated aluminum under intense force, which can help them achieve improved mechanical properties suitable for demanding applications.

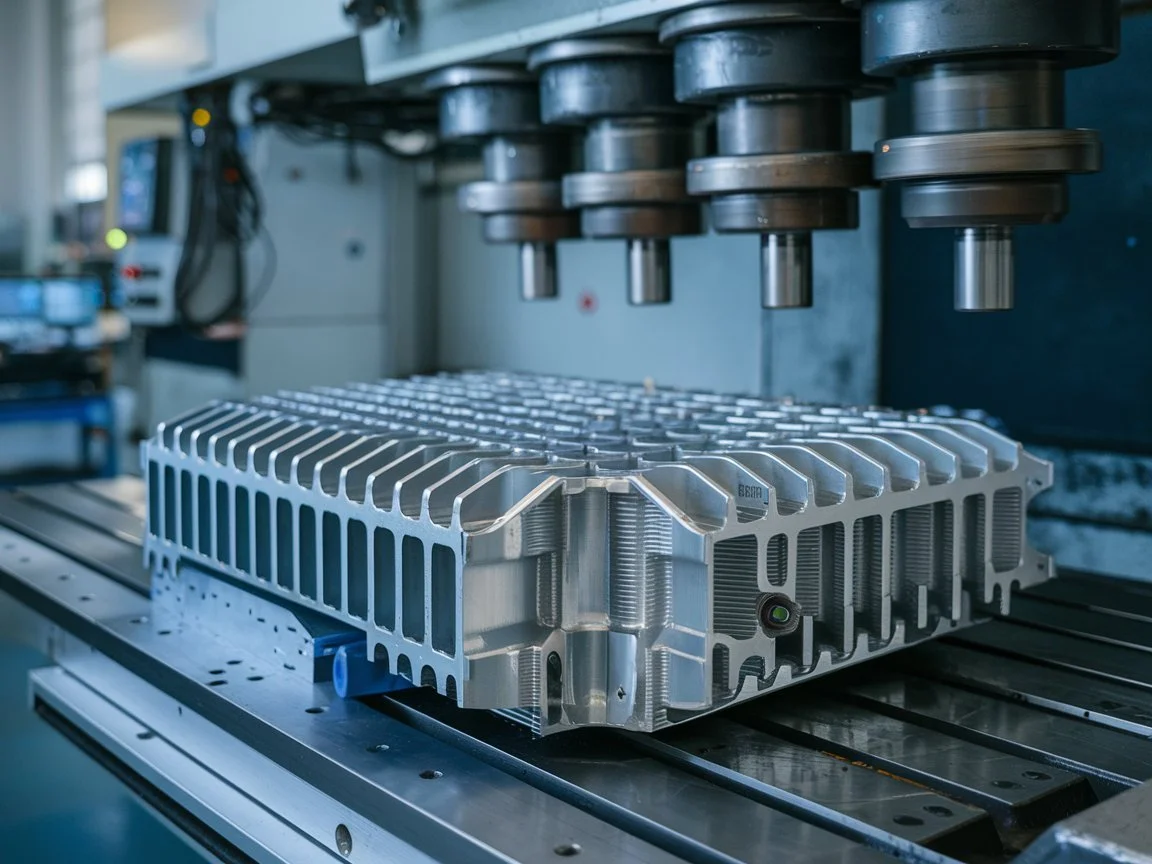

CNC Machined Custom Heat Sink

CNC-machined heat sinks provide versatility and precision in design, especially for low to medium-volume production. With computer-controlled machinery, these heat sinks can be created with intricate features such as custom cut-outs, through-holes, or complex contours to maintain tight tolerances and desired thermal performances.

Extruded Custom Heat Sink

Extruded heat sink offers cost-effectiveness for simple designs. Heat sink extrusion involves forcing heated aluminum through a die to create continuous profiles with enhanced surface area. Due to the relatively low labor requirements, this aluminum heat sink has a balanced combination of low manufacturing costs and reliable thermal performance.

Depending on the type of heat sink you choose, the dimensions can be as thin as 2mm and go up to 500mm in length. If you aren’t sure about your options, you may consult our team for advice. We will help you balance size and performance with tailored solutions.

Alloy Options for Aluminum Heat Sinks

Various aluminum alloys can be used to manufacture heat sinks with excellent strength-to-weight ratios and thermal capabilities.

You may refer to the table below for details about the most aluminum heat sink material options, which are labeled in both Japanese Industrial Standard (JIS) and American Society for Testing and Materials (ASTM) codes:

| JIS Code | ADC1 | ADC3 | ADC10 | ADC12 |

|---|---|---|---|---|

| ASTM Code | A413 | A360 | A380 | A383 |

| Thermal Conductivity (W/mK) | 121 | 113 | 96.2 | 96.2 |

| Coefficient of Thermal Expansion (μm/m°C) | 21.6 | 21 | 21.8 | 21.1 |

| Specific Heat Capacity (J/kg°C) | 963 | 963 | 963 | 963 |

| Melting Point (°C) | 574-582 | 557-596 | 540-595 | 516-582 |

| Tensile Strength (Mpa) | 290 | 317 | 324 | 310 |

| Yield Strength (Mpa) | 131 | 165 | 159 | 152 |

| Shear Strength (Mpa) | 172 | 179 | 186 | 20 |

| Fatigue Strength (Mpa) | 131 | 124 | 138 | 145 |

| Elongation (%) | 3.5 | 3.5 | 3.5 | 3.5 |

| Hardness (BHN) | 80 | 75 | 80 | 75 |

| Density (g/cm³) | 2.66 | 2.63 | 2.71 | 2.74 |

| Electric Conductivity (%IACS) | 31 | 29 | 23 | 23 |

Teamsworld also provides High Thermal Conduction Alloys (HTCA), so you can contact us for further details if you require these materials for high-performance heat sinks.

Our Aluminum Heat Sink Manufacturing Process

Step 1. Submit Files for Instant Quote

Submit your 2D or 3D files along with specific project details such as material, volume, and any customization needs. Our expert will provide an instant quote with free Design for Manufacturability (DFM) support to help you optimize your design.

Step 2. Place an Order

Once you're satisfied with the quote and DFM recommendations, simply place your order by sending us a confirmation. We will add you to a cloud-based project management platform to establish clear communication for this collaboration, ensuring a seamless transition from design to production.

Step 3. Production

With our state-of-the-art manufacturing facilities and skilled team, we will initiate production according to your requirements. In the meantime, you can track the progress of your order through our cloud-based platform which provides real-time updates for transparency.

Step 4. Quality Inspection

Our quality assurance team will conduct thorough inspections during and after production to ensure each aluminum heat sink meets your exact specifications while maintaining the highest standards of performance and reliability.

Step 5. Delivery

After carefully packing your custom aluminum heat sinks, we will deliver them through our global logistics network. We guarantee on-time arrival and safe handling for your satisfaction.

Success Stories by Our Clients

With Teamsworld’s expertise, we can help our clients enhance thermal management for various aluminum heat sink applications, from cooling systems in industrial machinery and LED lighting to temperature regulation in ICT components.

Here are some of our client’s success stories:

Elevated Outdoor Lighting Performance

A client in the lighting industry faced challenges in meeting growing demands for both functionality and aesthetic appeal. Through Teamsworld’s aluminum die-casting expertise and advanced post-processing techniques, the client achieved better heat dissipation, reduced material waste, and maintained sleek, modern designs for recessed wall lights and garden fixtures.

Reliable Heat-Dissipation for ICT Devices

Another one of our clients needed to improve heat dissipation for an ICT component to protect sensitive internal parts. By selecting a high-thermal-conductivity alloy and redesigning the heat sink structure, we helped this client significantly increase the heat dissipation area. Our DFM support also enabled faster innovation cycles for the client and reduced the component’s time-to-market for better consumer satisfaction.

Partner with Teamsworld for High-Quality Aluminum Heat Sinks

As a trusted aluminum heat sink supplier with over 35 years of experience, Teamsworld has built a reputation for delivering components with high design precision and functionality, such as casting and forging, casting aluminum, prototype tooling, and investment casting. By partnering with us you can experience:

Technical Expertise: Our expert team offers comprehensive design consultation with DFM support, ensuring that your heat sinks are optimized for performance and production efficiency.

Comprehensive Services: Strengthen manufacturing transparency for both customers and factories with optimized communication efficiency.

Quality Assurance: We are committed to delivering consistent quality and customer satisfaction, as demonstrated by our ISO 9001 and IATF 16949 certifications, which guarantee adherence to the highest industry standards.

Sustainable Manufacturing: As a B-Corp certified manufacturer, Teamsworld is also focused on reducing waste and carbon emissions throughout the production process, contributing to a greener, more sustainable world.

Contact us today to create a tailored thermal solution for your project!

FAQs About Aluminum Heat Sinks

What influences the cost of aluminum heat sinks?

Custom heat sinks made from premium aluminum (100–190W/m·K) offer excellent thermal performance, with cost and lead time varying by design and process.

Q

The cost of aluminum heat sinks may vary due to material type, manufacturing method, design complexity, and order volume. For instance, high-quality aluminum alloys may cost more but provide better thermal conductivity and durability. Intricate production methods that require higher precision and longer lead times may also lead to higher costs. Moreover, finishing options such as anodizing or sandblasting can add to the overall cost.

What is the typical lead time for custom orders?

Q

The lead time for custom aluminum heat sinks generally ranges from 2 to 6 weeks, depending on design complexity, material availability, and production volume. You can get in touch with our team for a more accurate estimate for your specific project.

How to choose an aluminum heat sink design?

Q

To ensure optimal performance, consider the following factors when selecting an aluminum heat sink:

Thermal Conductivity: This measures a component's ability to dissipate heat, so you should ensure the heat sink has sufficient capacity to accommodate the output of your device.

Size and Weight: The physical dimensions and weight of the heat sink should be compatible with your device's space constraints.

Environmental Conditions: If the heat sink will be exposed to harsh environments, consider choosing alloys that have enough strength and durability for better vibration tolerance and corrosion resistance.

Why Teamsworld ?

Since 1988, Teamsworld as a professional die-casting parts manufacturer and supplier in Taiwan, we integrate the authentic manufacturing process with innovative supply chain management from sourcing, engineering to logistics.

35 Years of Experience

Get expert consultation to design for manufacturing(DFM) from material to processing methods and speed time to market. Teamsworld offers production-grade quality, flexibility and delivers high-quality molds, samples, and parts on time.

Guided Technical Advice

Comprehensive experience in light metal OEM parts manufacturing for versatile industries. Full manufacturing service covers prototyping, aluminum/zinc die-casting, extrusion, CNC machining, and assembly & finishing.