Investment Casting

⇀ Complex Shapes with High Repeatability

⇀ Unmatched Precision, Time & Cost savings

⇀ Versatility & Metal Selection

Investment Casting

with Teamsworld

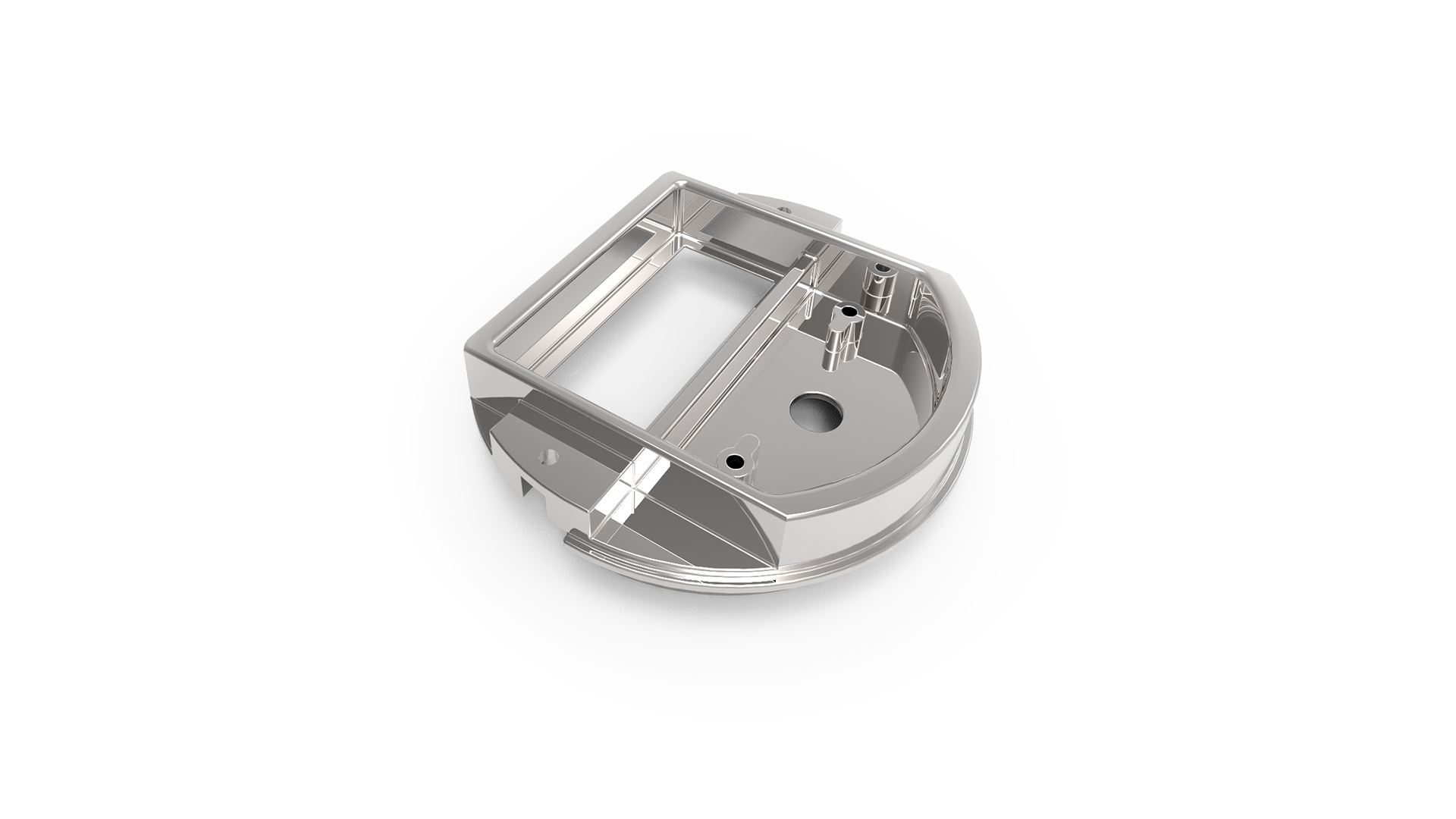

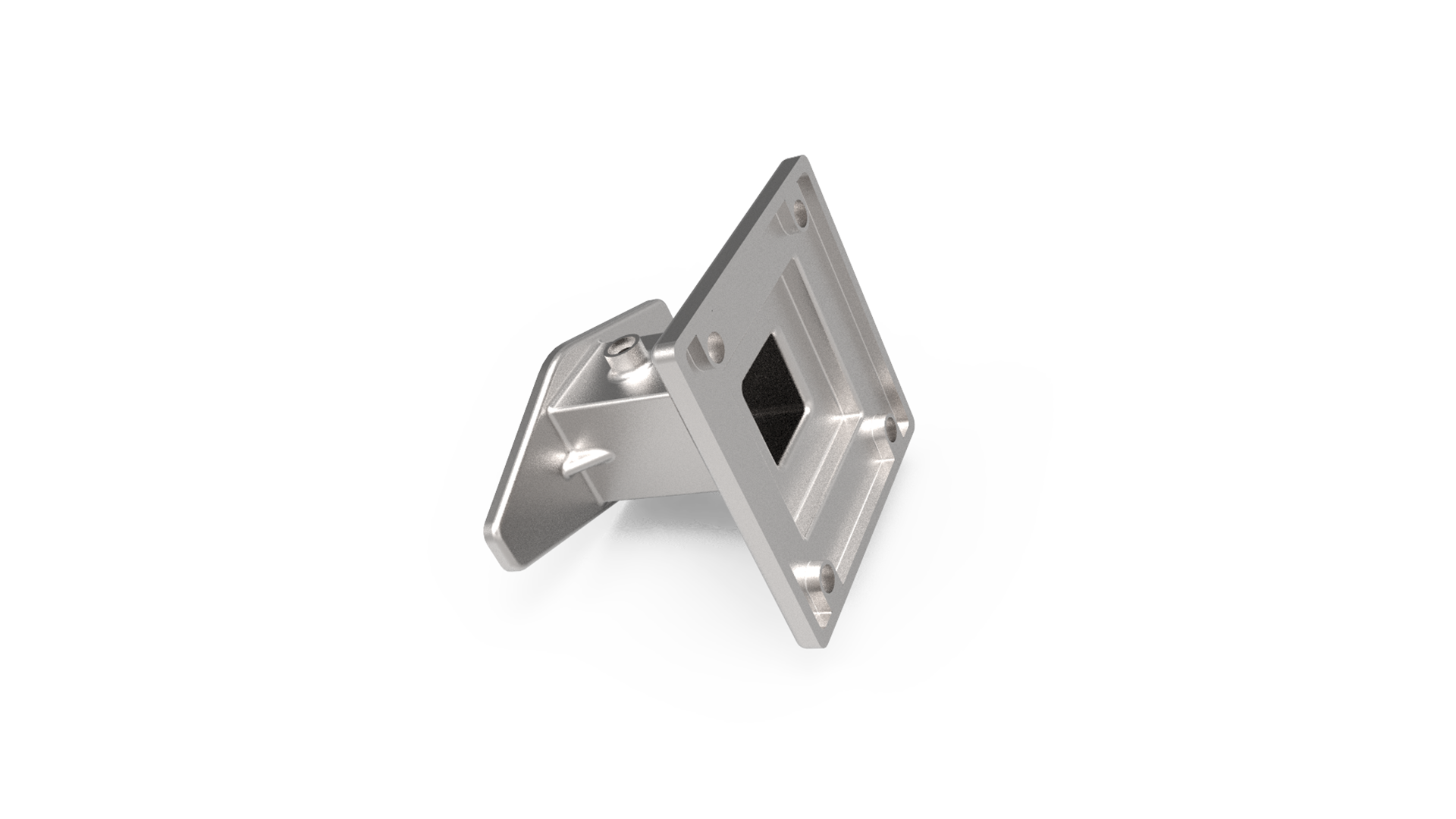

Teamsworld provides superior investment casting service, also known as lost wax casting, with a wide range of alloys for intricate designs and complex geometries. Our network of ISO-certified suppliers ensures casting reliability and minimizes deviations and defects, resulting in highly efficient manufacturing processes. With highly trained engineers and our expertise in supply chain management, we deliver highly precise investment cast parts and components at an affordable cost and with faster delivery times.

Investment Casting Material

Teamsworld offers a variety of alloys for investment casting, such as Stainless Steel, Low Alloy Steel, Aluminum Alloy, Carbon Steel, Supper Alloy, Copper Alloy, and Cast Iron. Our experts will assist in selecting the ideal material for your specific needs, saving on material costs, preventing casting defects, and minimizing the need for secondary processes.

Stainless Steel

Stainless Steel is highly durable and increasingly used in investment casting by designers and engineers. It's ideal for automotive gearbox parts, gears, lighting components, and industrial equipment. Common use stainless steel alloys , including:

●SUS304 ●SUS316 ●SUS316L

Commonly Cast Stainless Steel Alloys

Alloy

Common Usage

SUS304

Housings, automotive trim and exhaust systems, architectural and decorative applications.

SUS316

Housings, gears, plates, pumps and valves, aerospace component/part

SUS316L

Automotive exhaust systems, heat exchangers, springs & fasteners

Investment Casting Process

Teamsworld is capable of performing a complete investment casting process, including cast wax pattern, shell building, dewaxing, pouring & solidification, sawing/cutting, and custom surface treatment. Compared to other manufacturing methods, investment casting can provide undercuts, high definition, complex detail, and a smooth surface finish for various OEM precision parts economically.

Application of Investment Casting

Investment casting solutions are ideal for several industries due to its flexibility in design and the ability to produce complex shapes with high accuracy. Teamsworld specializes in investment casting parts for the automotive/transportation, medical device, and other general manufacturing industries.

Lighting

Automotive

Telecommunication

Medical Device

FAQ about

Investment Casting

Investment Casting is a precision casting process that can achieve high precision with minimal machining, welding, or assembly needed, resulting in time and cost savings.

What are the common alloys used in investment casting?

Q

It’s important to choose the correct investment casting material for your application from a variety of ferrous alloys, such as carbon steel, low-alloy steel, and stainless steel. You can also choose it from non-ferrous metals such as aluminum, brass, and bronze.

What industries use investment casting ?

Q

In addition to automotive/transportation, medical/dental industries, industries that use investment casting also include aerospace, lighting, and energy/power generation.

What kind of parts can be manufactured through investment casting?

Q

Investment castings are widely used in automotive industry (engine components, transmission parts, suspension parts), general manufacturing industries (pumps, valves, gears) and lighting industry (housings, reflectors, bulb sockets and connectors).

Why Teamsworld ?

Since 1988, Teamsworld as a professional die-casting parts manufacturer and supplier in Taiwan, we integrate the authentic manufacturing process with innovative supply chain management from sourcing, engineering to logistics.

35 Years of Experience

Get expert consultation to design for manufacturing(DFM) from material to processing methods and speed time to market. Teamsworld offers production-grade quality, flexibility and delivers high-quality molds, samples, and parts on time.

Guided Technical Advice

Comprehensive experience in light metal OEM parts manufacturing for versatile industries. Full manufacturing service covers prototyping, aluminum/zinc die-casting, extrusion, CNC machining, and assembly & finishing.