A380 Aluminum: Applications, Characteristics, and Future Trends

A380 Aluminum is a standout aluminum alloy, renowned for its unique blend of mechanical strength, casting adaptability, and cost-effectiveness. Utilized across various industries, including automotive, aerospace, and consumer goods, it has become a preferred material for manufacturers and engineers. Its applications range from intricate die casting to gravity casting, reflecting its versatility and alignment with modern industrial demands.

This blog post seeks to provide a comprehensive exploration of A380 Aluminum. From understanding its core advantages and applications to delving into its limitations, mechanical and physical properties, and future development trends, we aim to offer valuable insights for professionals and enthusiasts alike. Join us as we navigate the multifaceted world of A380 Aluminum, a material shaping the future of manufacturing.

What is A380 Aluminum?

In the industrial context, A380 Aluminum has become the alloy of choice for many high-pressure die casting and gravity casting applications. Its unique combination of silicon, copper, and magnesium, among other elements, contributes to its ability to be molded into complex geometries with a high degree of precision. This has led to its widespread adoption in sectors requiring stringent quality and performance standards, such as automotive, aerospace, and machinery manufacturing.

The utilization of A380 Aluminum reflects a broader trend in modern manufacturing toward materials that offer both functional adaptability and economic efficiency. Its historical development and continued relevance underscore its position as a vital material in contemporary industrial practices.

What Are the Key Advantages of A380 Aluminum?

Strength and Durability

A380 Aluminum's mechanical profile offers a robust solution for applications requiring high tensile strength and resistance to wear. Its structural integrity, even under demanding conditions, makes it a preferred choice for critical components in industries such as automotive and aerospace. The alloy's resilience contributes to extended product lifespans, reducing the need for frequent replacements and maintenance.

Cost-Effectiveness

Beyond its mechanical prowess, A380 Aluminum presents significant economic advantages. Its availability and compatibility with various casting processes, including high-pressure die casting, translate to reduced production costs. The alloy's ability to be molded into complex shapes without substantial waste or secondary machining further enhances its cost-efficiency. For manufacturers aiming to optimize both quality and budget, A380 Aluminum stands as a compelling option.

Environmental Impact

In an era where sustainability is paramount, A380 Aluminum's recyclability offers an environmentally responsible choice. Its capacity to be reused without degradation aligns with green manufacturing principles, contributing to a reduced carbon footprint. This alignment with environmental stewardship not only fulfills regulatory compliance but also resonates with the growing consumer demand for sustainable products.

Characteristics of A380 Aluminum

The following table summarizes the key mechanical, physical, and compositional characteristics of A380 aluminum, helping engineers quickly evaluate its suitability for die casting and industrial applications.

| Property Category | Description |

|---|---|

| Tensile Strength | High tensile strength enables A380 aluminum to withstand significant mechanical stress, making it suitable for load-bearing and structural applications. |

| Hardness | Excellent hardness provides resistance to wear and abrasion, contributing to long service life in industrial and automotive components. |

| Elongation | Balanced elongation allows limited flexibility without fracture, supporting functional design tolerance. |

| Density | Relatively low density helps reduce overall component weight, especially valuable in automotive and aerospace applications. |

| Melting Point | Suitable melting range enables efficient processing in high-pressure die casting and gravity casting. |

| Thermal Conductivity | Good thermal conductivity supports heat dissipation requirements in electronics and industrial housings. |

| Silicon Content | Silicon improves molten metal fluidity during casting and enhances wear resistance. |

| Copper Content | Copper increases mechanical strength and hardness, contributing to structural robustness. |

| Magnesium Content | Magnesium enhances overall alloy strength while maintaining lightweight characteristics. |

A380 Aluminum Applications

A380 Aluminum's unique properties have made it a sought-after material in various industrial sectors. Its adaptability and strength are particularly valued in the following areas:

Automotive Industry: Utilized in engine components, transmission housings, and structural parts, A380 Aluminum contributes to lightweight and fuel-efficient designs.

Aerospace Industry: Employed in aircraft structures and components, it offers a balance of strength and weight, essential for flight performance.

Machinery Manufacturing: From agricultural equipment to industrial machines, A380 Aluminum's durability and resilience make it suitable for heavy-duty applications.

A380 Aluminum's aesthetic appeal and functional adaptability extend its applications into consumer goods:

Electronics: From laptop casings to smartphone frames, A380 Aluminum offers a sleek appearance combined with the necessary thermal conductivity.

Kitchen Appliances: Its resistance to corrosion and ability to withstand temperature variations make it suitable for cookware and kitchen gadgets.

Sporting Equipment: In sports gear, A380 Aluminum's strength-to-weight ratio provides the needed performance without adding unnecessary bulk.

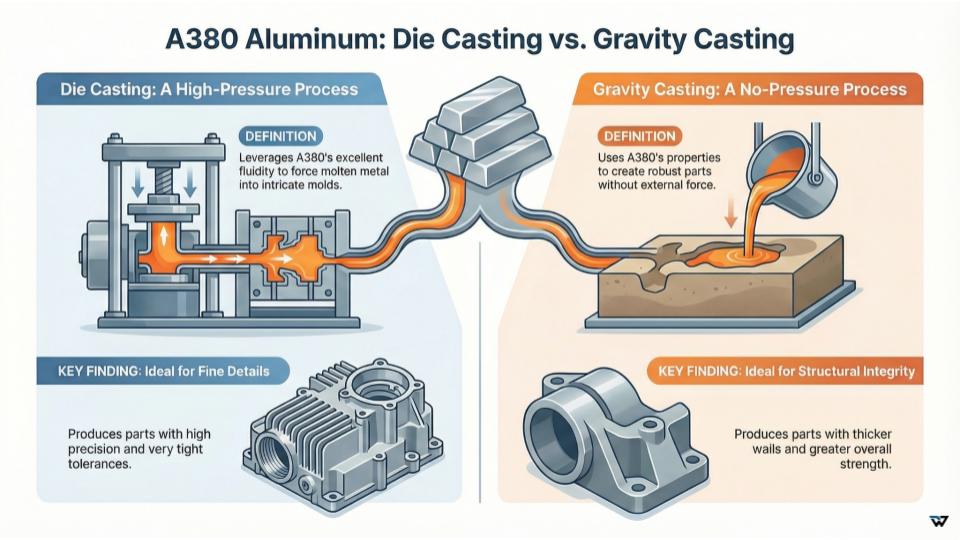

A380 Aluminum alloy in Die Casting vs. Gravity Casting

A380 Aluminum's compatibility with different casting processes has led to its widespread use in part production:

Die Casting: A380's excellent fluidity and ability to fill intricate molds make it ideal for high-pressure die casting, producing parts with tight tolerances and fine details.

Gravity Casting: In gravity casting, A380 Aluminum's properties allow for the production of robust parts without the need for high pressure, suitable for applications requiring thicker walls and greater structural integrity.

A380 Aluminum Application Limitations

A380 aluminum alloy is widely valued for its cost efficiency, good mechanical strength, and excellent castability. However, it is not suitable for every application, particularly when specific mechanical or environmental requirements exceed its performance range.

One key limitation of A380 aluminum is its susceptibility to hot cracking during casting. This issue can occur under improper thermal control, especially when cooling rates and mold temperatures are not carefully managed. As a result, precise process control is essential to ensure dimensional stability and structural integrity in critical components.

In addition, A380 aluminum is not the optimal choice for applications demanding very high tensile strength or exceptional corrosion resistance. For environments involving aggressive chemicals, outdoor exposure, or high structural loads, alternative alloys may perform better. For example, 7075 aluminum is often selected for its superior tensile strength, while 6061 aluminum is preferred for its excellent corrosion resistance and balanced mechanical properties.

Understanding these limitations allows engineers and manufacturers to make informed material decisions and avoid performance trade-offs. In summary, A380 aluminum excels in high-volume, cost-sensitive casting applications, but when strength or corrosion resistance is the primary requirement, selecting a more specialized aluminum alloy is recommended.

Future Trends: Development Trends of A380 Aluminum

A380 aluminum continues to play a critical role in modern manufacturing thanks to its balance of mechanical performance, castability, and cost efficiency. From automotive and agricultural machinery to consumer electronics and industrial equipment, its adaptability across die casting and gravity casting processes makes it a reliable material choice for high-volume production.

As industries move toward lightweight design, sustainability, and faster production cycles, A380 aluminum remains a practical and future-ready alloy. For manufacturers seeking optimized casting solutions, alloy selection guidance, or global supply chain support, Teamsworld offers integrated engineering and manufacturing expertise to help bring your projects to market efficiently, feel free to contact us at Teamsworld.

FAQ

Q1: What is A380 aluminum best used for?

A380 aluminum is best suited for high-pressure die casting applications that require good strength, excellent castability, and cost efficiency. It is widely used in automotive housings, electronic enclosures, and industrial components.

Q2: Is A380 aluminum suitable for gravity casting?

Yes. While A380 aluminum is primarily used in high-pressure die casting, it can also be applied in gravity casting for thicker-walled parts where extreme dimensional precision is not required.

Q3: How does A380 aluminum compare to A356 aluminum?

A380 focuses on cost efficiency and castability, while A356 offers better heat-treatable mechanical properties and corrosion resistance. The choice depends on performance requirements and production volume.

Q4: Can A380 aluminum be used in automotive and agricultural machinery?

Absolutely. A380 aluminum is commonly used in automotive transmission housings, engine brackets, and agricultural machine components due to its durability and manufacturing efficiency.

Q5: Is A380 aluminum environmentally friendly?

A380 aluminum is recyclable and supports sustainable manufacturing by reducing material waste and enabling lightweight designs, contributing to lower energy consumption across product lifecycles.