Advancing Precision Manufacturing: Unveiling the High-Pressure Die Casting Process

In today's dynamic manufacturing landscape, the high-pressure die casting (HPDC) process stands tall as an innovation powerhouse, transforming the production landscape for intricate metal components. This comprehensive guide aims to delve into the nuances of HPDC, elucidating its processes, materials, advantages, disadvantages, and versatile applications across industries.

Understanding High-Pressure Die Casting

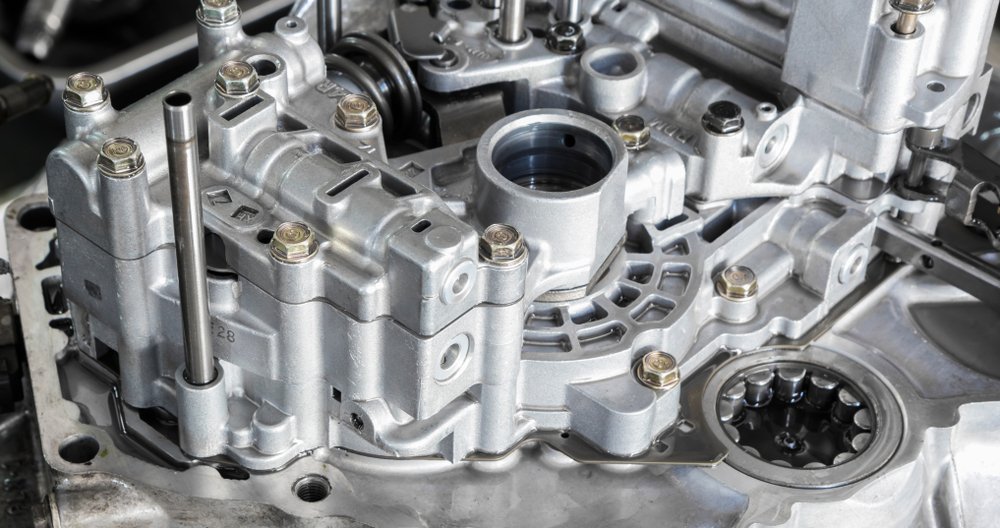

High-Pressure Die Casting (HPDC) emerges as a hallmark of efficiency in manufacturing, revered for its capability to fabricate intricate and precise metal components with unparalleled accuracy and speed. At its core, HPDC entails the injection of molten metal into a steel mold cavity under high pressure, yielding meticulously crafted parts with exceptional surface finish and dimensional accuracy. The significance of HPDC resonates across diverse sectors, ranging from automotive and aerospace to consumer electronics, where the demand for intricately shaped metal parts reigns supreme.

Types of High-Pressure Die Casting

High-pressure die casting (HPDC) is categorized into two fundamental processes: hot chamber and cold chamber casting.

Hot Chamber Die Casting is noted for its operational efficiency and swift cycle times. In this method, molten metal is injected straight from the furnace into the die. Metals with lower melting points, such as zinc, are commonly used in this process, making it a go-to technique for large-scale production demands.

Cold Chamber Die Casting differs in that it involves transferring molten metal into a separate chamber before injection into the die. This approach is more suitable for metals with higher melting points, like aluminum and magnesium, due to the method's capacity to handle the increased heat. The cold chamber process is particularly adept at creating larger, more intricate parts requiring detailed control throughout the casting operation.

Both techniques are integral to HPDC and are selected based on the specific requirements of the production, the material properties needed, and the complexity of the components being manufactured.

Materials Compatible With High-Pressure Die Casting

Aluminum alloys are indispensable in high-pressure die casting (HPDC), offering unmatched versatility across several critical industry sectors. Their unique properties facilitate the production of parts that are not only structurally sound but also conducive to high-performance applications where weight and thermal management are paramount.

Automotive Sector: In automotive engineering, aluminum alloys are pivotal for crafting lightweight yet robust components. Specifically, they are used for engine blocks and transmission housings, where the material’s excellent heat dissipation qualities and resistance to corrosion significantly improve vehicle efficiency and longevity. Aluminum's lightweight nature contributes to fuel efficiency and reduced emissions, aligning with the automotive industry's push toward sustainability.

Electronics and Telecommunications: Aluminum’s superior thermal conductivity makes it the material of choice for electronic housings and heat sinks within devices ranging from smartphones to high-powered computing systems. These components are essential for dissipating heat effectively, ensuring the longevity and reliability of sensitive electronic components. Aluminum's malleability allows for the precision casting of thin-walled structures that encapsulate complex internal geometries, providing optimal protection and thermal management in a compact form.

Aerospace Applications: The aerospace industry benefits from the use of aluminum alloys in parts such as landing gear housings and structural components. The material's strength-to-weight ratio enhances the aerodynamic performance of aircraft while ensuring safety and durability. Furthermore, aluminum's resistance to temperature variations and its lightweight properties are crucial for minimizing energy consumption and maximizing payload capacity.

Energy Sector: Aluminum alloys play a significant role in the renewable energy sector, particularly in the construction of components for solar panels and wind turbines. Heat sinks and housings made from aluminum not only provide structural integrity but also ensure efficient thermal management, crucial for maintaining the performance of energy systems.

High-Pressure Die Casting Process Explained

The HPDC process unfolds through several meticulously orchestrated stages, each pivotal in the production of high-quality metal components.

Mold Preparation: The journey commences with meticulous mold design and preparation, where experienced tool designers leverage advanced CAD/CAM software to craft intricate mold designs. These designs optimize material flow and minimize defects, ensuring the faithful replication of the desired component. The mold, machined from high-grade tool steel and heat-treated for durability, serves as the cornerstone of the casting process.

Injection: With the mold poised for action, molten metal is injected into the cavity with precision under high pressure. This critical stage demands meticulous control to achieve uniform filling and minimize defects such as porosity and shrinkage. Advanced die casting machines equipped with programmable controls and monitoring systems facilitate precise adjustment of injection parameters, including temperature, pressure, and injection speed.

Part Removal: As the molten metal solidifies within the mold cavity, the formed part awaits its liberation. Automated ejection systems or manual extraction methods delicately remove the casting from the mold, ensuring minimal damage or distortion. The ejected parts undergo a rigorous inspection to verify dimensional accuracy, surface finish, and other quality attributes.

Trimming: With the casting freed from its mold confines, excess material is meticulously trimmed to refine the component to its final specifications. Precision trimming operations, including machining, deburring, and surface finishing, are undertaken to eliminate excess flash, gating, and other casting defects. Advanced CNC machining centers and robotic trimming systems ensure consistency in part geometry and surface finish, elevating the overall quality and performance of the finished components.

Advantages and Disadvantages of High-Pressure Die Casting

The HPDC process has advantages, including high production efficiency, intricate design capabilities, and cost-effectiveness. However, like any manufacturing process, it also harbors certain limitations. While HPDC offers unparalleled efficiency and precision, it may present challenges such as restricted material options and higher initial tooling costs.

Applications of High-Pressure Die Casting

Automotive Industry: HPDC is instrumental in manufacturing critical powertrain components, including engine blocks, transmission systems, and chassis parts. These components benefit from the high strength, lightweight, and dimensional accuracy that HPDC provides, contributing significantly to vehicle performance, safety, and fuel efficiency. For instance, the use of aluminum alloys in engine components not only reduces the overall vehicle weight but also enhances heat dissipation, a critical factor in improving engine efficiency and lifespan.

Aerospace Sector: In aerospace, HPDC is used to create structural components, such as brackets, and housing for avionics, where precision and strength-to-weight ratio are non-negotiable. The method’s ability to produce parts that withstand extreme conditions while minimizing weight is vital for aerospace applications, directly impacting fuel consumption and payload capacity.

Electronics Manufacturing: The electronics industry relies on HPDC for the production of intricate enclosures and heat sinks. These components are essential for protecting sensitive electronics and managing the heat generated by devices, ensuring reliability and longevity. The precision of HPDC allows for the creation of thin-walled enclosures that are both lightweight and robust, suitable for consumer electronics, telecommunications equipment, and large computing systems.

Real-World Impact of HPDC: The transformative impact of HPDC is evidenced through its application in creating lighter and more efficient automotive engines that contribute to significant reductions in CO2 emissions. In aerospace, HPDC-produced parts have been crucial in the development of lighter aircraft that consume less fuel and have a lower environmental footprint. In the realm of consumer electronics, the method has enabled the design of sleek, durable, and highly functional devices that meet the increasing demands for performance and aesthetics.

By integrating HPDC into their manufacturing processes, industries are not only able to achieve higher levels of precision and efficiency but also drive innovation in product development and design. The technique’s contribution to lightweighting, energy efficiency, and sustainability underscores its vital role in the future of manufacturing across various sectors.

Teamsworld's Insight: Mastering the High-Pressure Die Casting Process

At Teamsworld, our specialization in high-pressure die casting (HPDC) is not just about mastering a manufacturing process—it's about pushing the boundaries of precision, efficiency, and innovation in metal component fabrication. Our dedication to HPDC stems from a deep understanding of its critical role across industries and our commitment to delivering solutions that meet the exacting standards of our clients. By leveraging state-of-the-art technology and a wealth of expertise, we help transform concepts into reality, producing components that are integral to the advancement of automotive, aerospace, electronics, and more.

Our focus on HPDC is driven by the technique's unparalleled ability to produce durable, intricate, and lightweight parts. This commitment is evidenced in our continuous investment in research and development, ensuring that we stay at the forefront of technological advancements in die casting. Teamsworld's capabilities extend beyond mere production; we offer comprehensive support from Design for Manufacturing(DFM) to final product, ensuring that every aspect of the HPDC process is optimized for quality and sustainability.