Smart Die Casting: Transforming Aluminum Casting Through Digital Manufacturing Platform

As global industries accelerate toward sustainability and electrification, casting aluminum has become the foundation for building lighter, stronger, and more efficient products. From die-cast components used in EVs and communication devices to precision aluminum parts manufacturing for next-generation lighting systems, the demand for smarter production continues to rise. Yet, the critical innovation shaping the future of manufacturing is no longer found solely in machines; it lies in how design, production, and supply chain intelligence are connected.

This fundamental evolution defines the rise of Smart Die Casting, where digital manufacturing platforms like Teamsworld are redefining how OEMs and Tier 1 suppliers approach high-precision aluminum die casting.

Redefine Smart Die Casting

Historically, the term Smart Die Casting referred narrowly to factory automation — where sensors monitored melt temperature, controlled pressure, or detected surface defects in real time. While these in-machine systems remain vital, they address only one dimension of modern global production.

Today, Smart Die Casting has expanded far beyond the factory floor. It now encompasses intelligent, systemic coordination that connects initial design, advanced tooling, and global supply chain execution. Instead of relying solely on localized AI, global manufacturers require smart supply chain intelligence, the capability to maintain consistent quality, optimize production costs, and ensure flexibility across multi-regional operations.

Teamsworld’s digital manufacturing platform bridges these needs by aligning die-cast component design with real-world production execution. Through digital coordination and early DFM collaboration, Teamsworld empowers customers to achieve scalable, cost-efficient aluminum parts manufacturing — transforming Smart Die Casting into a truly data-driven, globally connected process.

DFM Intelligence: Where Smart Casting Begins

The most valuable improvements in aluminum die casting occur before the first mold is cut. Design for Manufacturability (DFM) transforms costly post-tooling corrections into proactive design optimizations, saving weeks of delays and tens of thousands in rework expenses.

The DFM Process

| Stage | Description |

|---|---|

| Stage 1: Early Collaboration | Engineers review CAD files during product conceptualization, when design changes require hours of engineering time rather than weeks of tooling modifications. |

| Stage 2: Geometry Optimization | Analysis identifies wall thickness issues (targeting 2.5–4mm for aluminum), draft angles (minimum 1–3°), and undercut configurations that impact part ejection and mold complexity. |

| Stage 3: Process Simulation | Computational fluid dynamics validates metal flow patterns, predicting porosity zones, air entrapment risks, and shrinkage cavities before steel cutting. |

| Stage 4: Material Selection | Engineers recommend optimal aluminum alloys balancing mechanical properties (tensile strength, elongation) with casting process characteristics (fluidity, solidification behavior). |

Industry Applications

Automotive: Battery enclosure designs optimized for thin-wall strength and crash performance.

5G Telecom: Heat sink geometry maximizing surface area while maintaining die-castability.

Security System: Weather-resistant housings balancing IP67 sealing with thermal management.

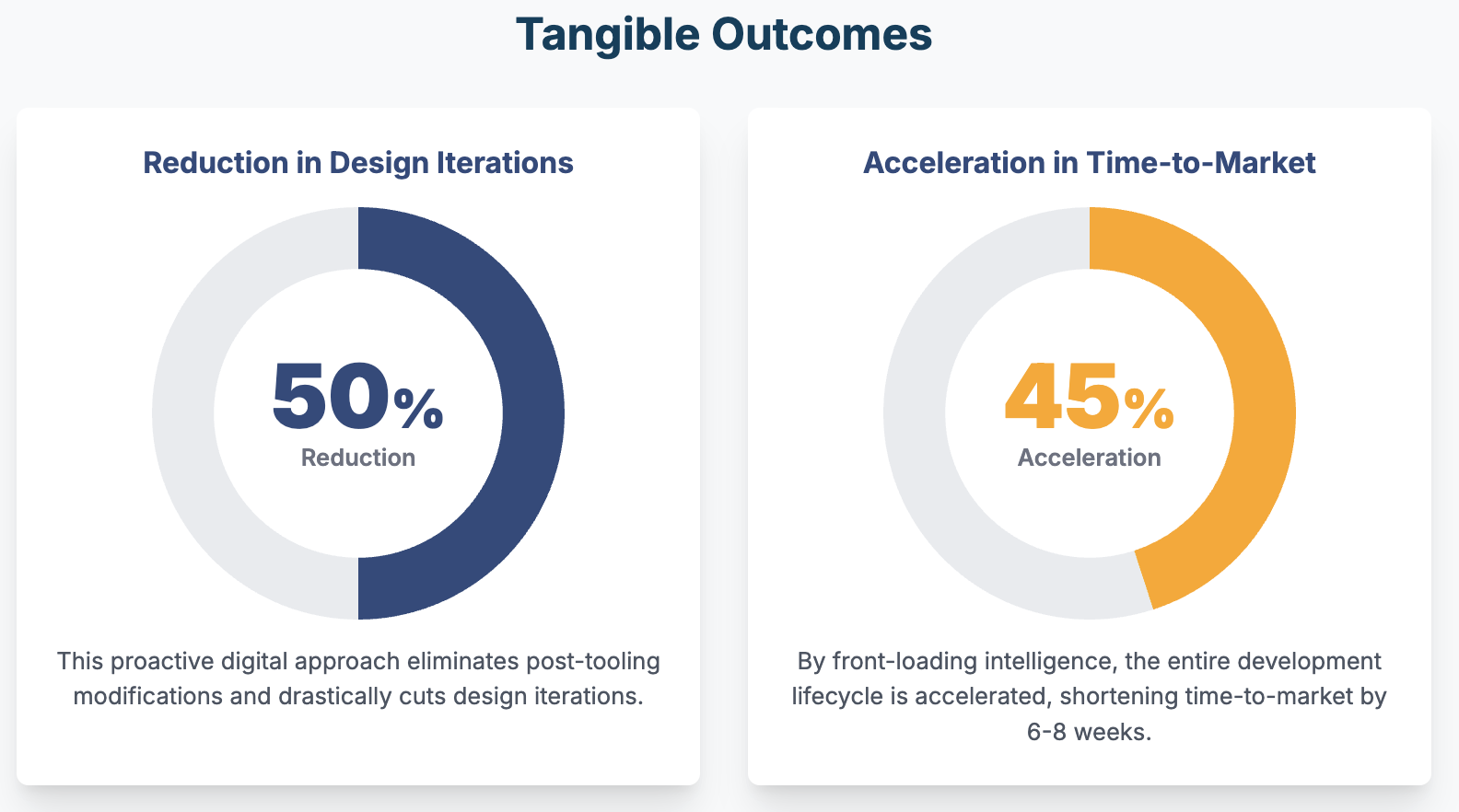

This proactive approach reduces design iterations by 50%, eliminates post-tooling modifications, and accelerates time-to-market by 6-8 weeks compared to reactive problem-solving.

Smart vs. Traditional Die Casting

Smart Die Casting is not merely automation; it is about making smarter, data-driven decisions across the entire production lifecycle.

| Aspect | Traditional Die Casting | Smart Die Casting (Teamsworld Approach) |

|---|---|---|

| Focus | Factory-level efficiency | Global design and supply chain coordination |

| Process | Reactive troubleshooting | Proactive DFM and predictive planning |

| Visibility | Localized | Cross-site digital transparency |

| Outcome | Cost-driven | Agility, quality, and sustainability-driven |

Case Insight: Die-Cast Heatsinks and Structural Components

One of the most demanding applications for Smart Die Casting lies in die-cast heatsinks and structural aluminum housings for Electric Vehicles (EVs) and high-performance lighting systems.

These components require precise control over material flow, thermal dissipation, and structural integrity. Teamsworld’s expertise in casting aluminum for such applications ensures both dimensional accuracy and reliable thermal performance.

Lighting: Die-cast heatsinks not only improve LED efficiency but often serve as integral structural parts of the fixture.>> Learn more about Outdoor Lighting Solution

Automotive: The aluminum die-cast parts support critical vehicle lightweighting goals while maintaining crashworthiness and durability.>> Learn more about Automotive Lightweight Solution

By facilitating both rapid prototyping (under 500 pcs) and scalable volume production, all coordinated through a single digital platform, Teamsworld ensures continuous testing, design iteration, and seamless scale-up.

Achieve Sustainable Scalability through Intelligent Partnerships

In the age of Industry 4.0, advanced machinery is necessary but insufficient. Manufacturers require partners capable of bridging digital intelligence, material expertise, and cross-border execution.

Teamsworld stands at the intersection of these needs, acting as both a manufacturing advisor and a production partner. We help global OEMs achieve:

Early-stage DFM optimization for casting aluminum parts.

Dual-location manufacturing flexibility across Taiwan and Vietnam.

Transparent project management through digital coordination.

Scalable, sustainable production aligned with global ESG goals.

For manufacturers seeking to modernize their aluminum die casting strategies or optimize die-cast heatsink designs, Teamsworld offers not just production capability, but the intelligence to make every manufacturing decision smarter.