Why Gigacasting is Transforming EV Manufacturing?

The electric vehicle revolution is reshaping automotive manufacturing at every level, from battery technology to production methodologies. Among the most significant innovations is gigacasting—a revolutionary die casting technique that promises to redefine how electric vehicles are built. As automakers race for greater efficiency, sustainability, and cost-effectiveness, gigacasting has emerged as a game-changing technology.

EV Market Growth and the Rise of Gigacasting

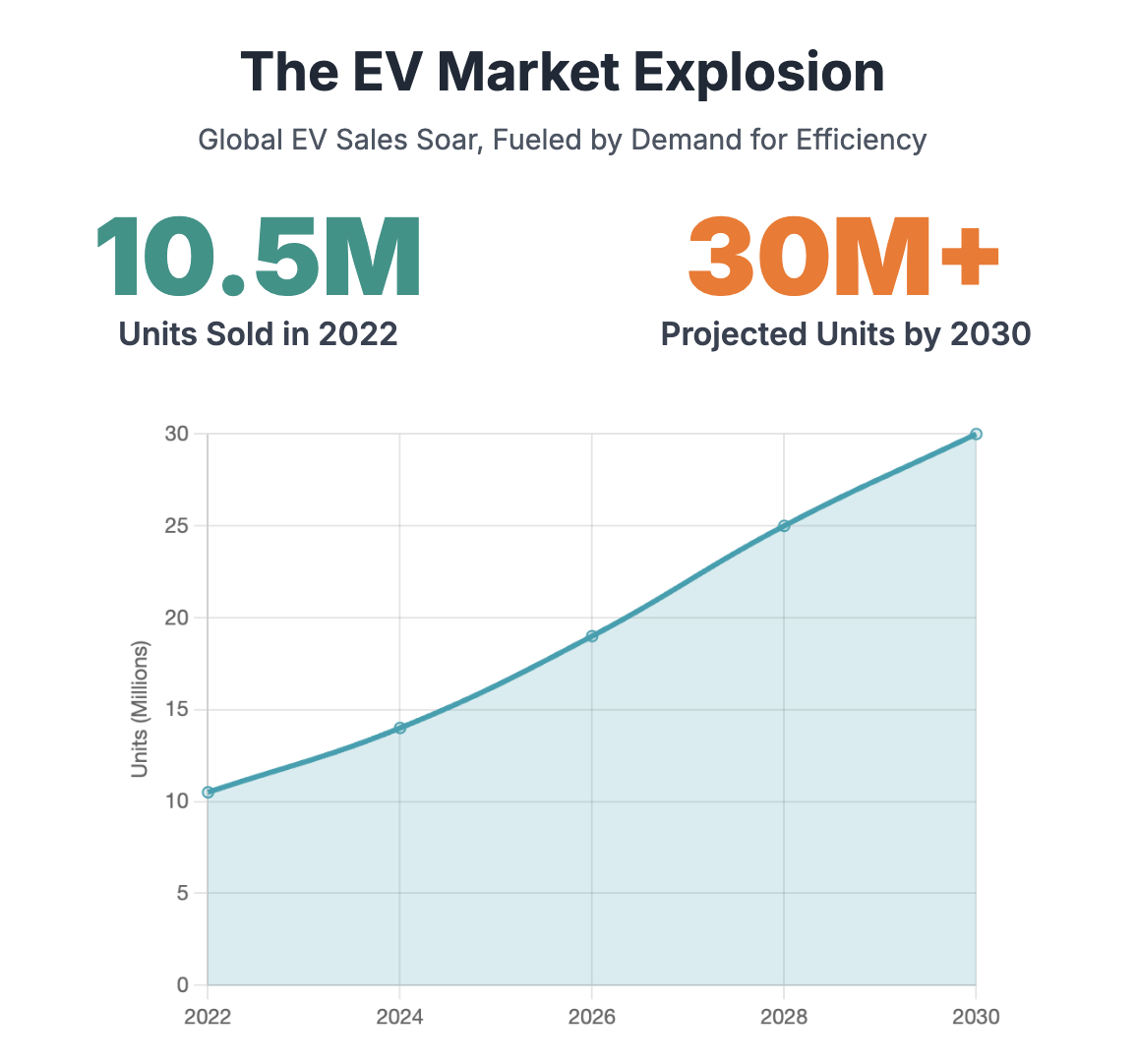

The global electric vehicle market has experienced unprecedented growth, with global electric vehicle sales set for record-breaking year despite regional variations in market dynamics. Global EV sales reached 10.5 million units in 2022 and are projected to exceed 30 million units by 2030, representing a compound annual growth rate of over 20%. This explosive expansion has intensified pressure on manufacturers to develop more efficient production methods.

Die casting has long been a cornerstone of automotive manufacturing, but the unique demands of electric vehicles—such as the need for large battery pack housings and improved structural integrity—have pushed conventional methods to their limits.

This is where gigacasting comes in. It's a new approach that scales up die casting to produce massive, single-piece structural components. This technology represents a paradigm shift from traditional multi-part assemblies to integrated, one-piece solutions that dramatically simplify vehicle architecture. Tesla's pioneering implementation of gigacasting has demonstrated its potential to transform manufacturing economics, making it a focal point for the entire automotive industry.

What is Gigacasting? (A New Era of Automotive Die Casting)

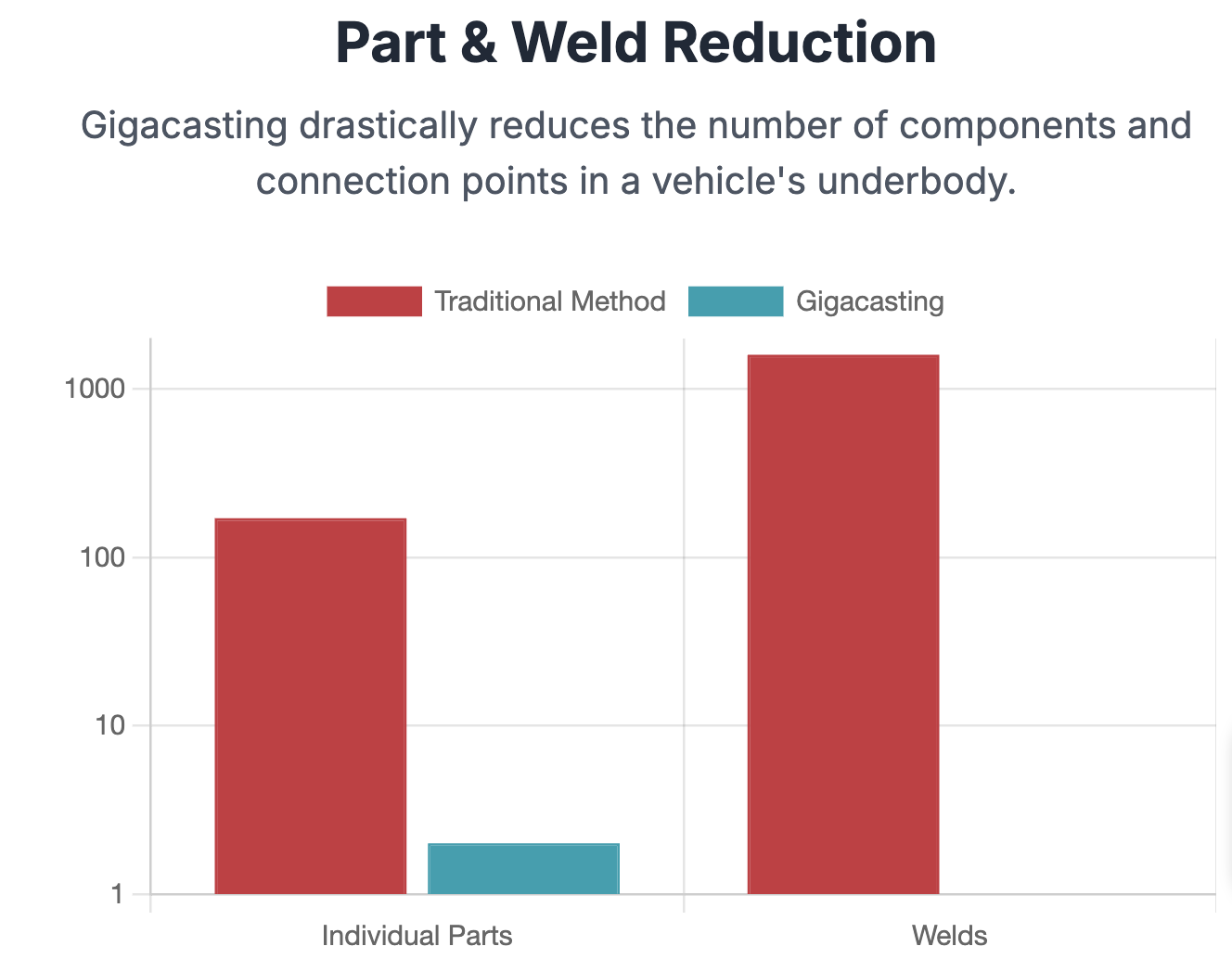

Gigacasting is the large-scale aluminum die casting process that creates substantial structural components, typically weighing between 70 to 100 kilograms or more, in a single operation. Unlike traditional automotive manufacturing that relies on hundreds of stamped steel parts welded together, gigacasting produces entire vehicle sections as unified aluminum castings.

Key Differences: Gigacasting vs. Traditional Methods

| Characteristic | Traditional Manufacturing | Gigacasting |

|---|---|---|

| Methodology | Welding hundreds of parts | Casting one single component |

| Production Time | Hours-long assembly | Minutes-long casting |

| Complexity | High (many parts, welds) | Low (one integrated part) |

Tesla pioneered gigacasting with the Model Y, where a single gigacast piece replaced 70 individual parts and numerous welding operations for the rear underbody structure.

The process uses massive die casting machines with clamping forces exceeding 6,000 tons—often referred to as "Giga Presses."

This approach requires significant innovations in alloy development, mold design, and casting process control to ensure consistent quality across the entire component.

The fundamental difference lies in integration and scale. Traditional body construction involves extensive welding and complex assembly sequences, where each joint is a potential weakness. Gigacasting eliminates many of these joints by creating a single, monolithic component, which fundamentally changes how vehicles are designed and assembled.

Key Benefits of Gigacasting in EV Production

Gigacasting offers a trifecta of benefits: reduced weight, lower costs, and enhanced safety.

Lightweighting & Sustainability

Gigacasting can reduce structural weight by 10-20% compared to traditional methods by eliminating numerous individual components and fasteners. For electric vehicles, where every kilogram saved translates to improved range and efficiency, this is particularly valuable.

Recycled Aluminum: Aluminum castings are highly recyclable, with recycled aluminum requiring only 5% of the energy needed to produce primary aluminum.

Reduced Material Usage: The simplified process reduces overall material usage and eliminates the need for numerous component fabrication steps, aligning with sustainability objectives.

Cost Reduction

While the initial investment in gigacasting equipment is substantial, the operational savings are significant.

Eliminated Labor and Robots: Tesla reports that gigacasting eliminates hundreds of robots, extensive welding operations, and complex assembly sequences.

Faster Production Cycle Time: Gigacasting can produce large structural components in minutes, a dramatic reduction from the hours required for traditional body-in-white assembly.

Safety & Performance

Gigacasting delivers superior structural integrity compared to multi-part assemblies.

Predictable Crash Performance: Gigacast components have consistent material properties throughout their structure, providing more predictable and effective energy absorption during a crash.

Fewer Failure Points: The elimination of joint interfaces reduces the risk of corrosion and fatigue failures over the vehicle's service life.

Gigacasting Beyond Tesla: Industry Adoption

Tesla's success has spurred widespread industry interest.

Volvo plans to implement gigacasting in its next-generation EVs.

Toyota has committed significant resources to developing its gigacasting capabilities.

Chinese EV manufacturers like NIO, XPeng, and BYD have aggressively pursued the technology to gain a competitive edge. For example, Geely's EV brand Zeekr is using it for the rear underbody of its models.

The supply chain is also responding. Major Tier 1 suppliers like Giga Metals, Ryobi, and UBE Machinery have invested billions in equipment and development. These investments reflect confidence that gigacasting will become a standard manufacturing approach for electric vehicles.

Challenges and Future Outlook of Gigacasting

Despite its promise, gigacasting faces significant hurdles for widespread adoption.

High Tooling Costs: Gigacasting dies are extremely large and complex, often costing several million dollars per set. Tool life and maintenance are critical factors.

Repair and Maintenance: Unlike traditional welded structures that can often be repaired locally, a damaged gigacast component may require a complete replacement, raising concerns about collision repair costs and insurance.

Limited Market Applicability: Gigacasting economics favor high-volume vehicles where the substantial capital investment can be effectively amortized. Smaller vehicles or low-volume applications may not justify the investment.

Future developments will likely focus on:

AI and Smart Manufacturing: AI-driven process optimization to improve casting quality and reduce scrap rates.

Advanced Materials: New aluminum alloys with improved castability and strength.

Integration: The convergence of gigacasting with technologies like additive manufacturing for tooling.

As the technology matures and costs decrease, gigacasting may extend beyond EVs to other automotive segments and, eventually, other industries requiring large, lightweight structural components.

Ready to discover how gigacasting can revolutionize your manufacturing operations? At Teamsworld, we have deep expertise in advanced automotive die casting technologies and their implementation. Our team can help you evaluate gigacasting opportunities for your specific applications and enhance your competitive position in the evolving automotive landscape.